Porcelain Paving Guide

Are you unsure what porcelain paving is? Struggling to understand the difference between porcelain paving slabs and outdoor porcelain tiles? Our comprehensive guide explains what porcelain paving is, the styles available, the requirements for laying porcelain paving and the many benefits of choosing porcelain paving for your patio. We even include a handy laying porcelain paving video. Read on to learn everything you need to know about porcelain paving.

Topics covered

- What is porcelain paving?

- What styles are available?

- How do you lay porcelain paving?

- Pros and cons of porcelain paving

- Finding an experienced installer

What is porcelain paving?

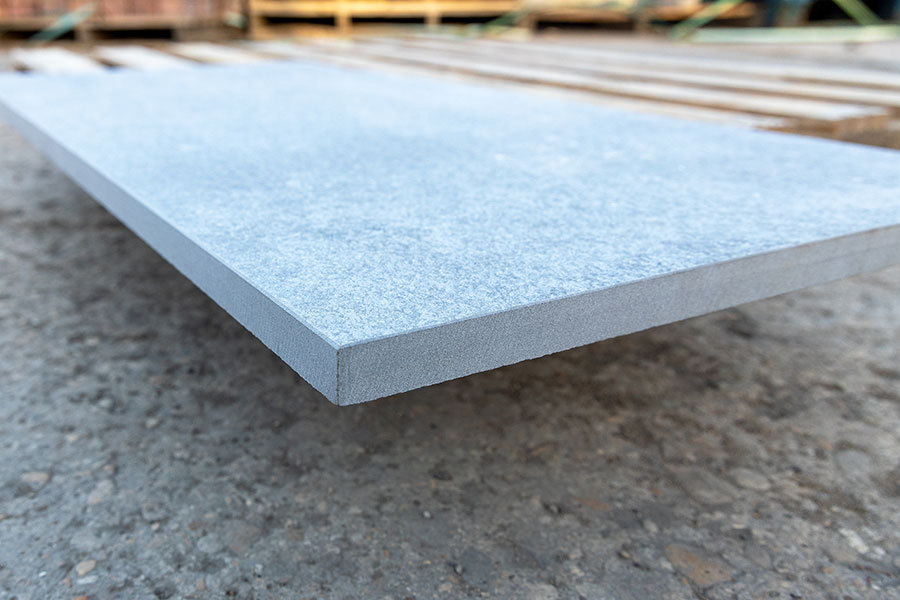

Porcelain paving slabs, sometimes referred to as outdoor porcelain tiles, are very similar to porcelain tiles used for interior walls and floors. They are made using the same materials and processes but tend to be thicker than tiles at 20-25mm. To make porcelain paving slabs, ground sand and feldspar are combined with very fine clays before the mixture is compressed at high pressure and fired at up to 1200 degrees centigrade. The high firing temperature causes vitrification, a process where the silica in the mixture turns to glass, sealing any air pockets in the body to produce an extremely dense slab with a water absorption rate of 0.5% or less. Porcelain paving slabs use digital printing to apply a design, colours patterns and even natural wood and stone effects, before the final firing process.

Porcelain paving slabs are stronger, denser and absorb significantly less water than equivalent natural stone and concrete paving slabs. These attributes make them frost resistant, more durable, scratch resistant and easier to clean and maintain than other types of paving. The manufacturing process also ensures accuracy and conformity, resulting in very little variation in size and shape and this makes porcelain paving easy to lay and grout lines can be narrower which improves the appearance.

The strength of porcelain paving slabs makes them suitable for practically any application, from paths and patios to driveways and wall cladding. Speaking of wall cladding, leading brands such as Digby, Pavestone, Brett, and Bradstone offer colour matched porcelain wall cladding in smooth and stone effect styles to perfectly compliment porcelain paving.

What styles of porcelain paving are available?

The design on porcelain paving slabs is printed using special inks. The design possibilities are endless, particularly with modern digital printing techniques, and this means that porcelain paving is available in a huge variety of patterns and effects mimicking natural materials. Stone and wood effects are particularly popular but patterns and plain colours are also widely available. Porcelain paving slabs feature either a flat and lightly textured surface or a riven surface to mimic natural stone or the grain of timber. Like other types of patio paving, porcelain is available in a variety of individual sizes and project packs.

The modern appearance of porcelain paving means that simple laying patterns, often using one size of paving slab, are popular. That said, rustic styles are available in mixed sizes for creating a more traditional random pattern look.

How do you lay porcelain paving?

This is not intended to be a definitive porcelain paving installation guide, here we will cover key points of installation.

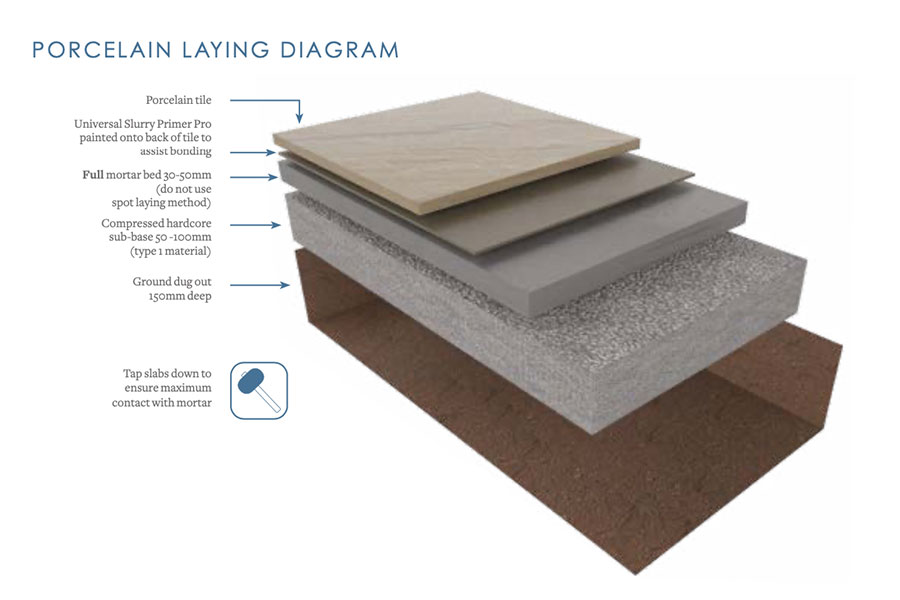

The process of laying the base for a porcelain paving is the same as most natural stone and concrete paving slabs, you can read more about this in our guide “How to lay a patio”. The differences in the laying process for porcelain paving slabs, compared to concrete slabs some types of natural stone, are that they require priming before laying and bedding on a stronger mortar mix is recommended. Both differences in the laying process are due to the extremely low porosity of porcelain, the very attribute that makes them so strong, durable and able to withstand all weather conditions.

Prior to installing porcelain paving it is important to prime the underside of the slabs with a slurry primer. This helps the slabs bond to the mortar when they are laid. Simply apply the slurry primer to the reverse of the slab with a large fence or wall papering brush just before laying. Slurry primer is a glue, if it gets on to the top surface of the slab it must be washed off with a wet sponge quickly to prevent it drying.

Many paving professionals recommend laying porcelain paving on stronger mortar mix to ensure a good bond. Pavestone recommend a ratio of 5 parts water to one of cement for their porcelain paving, when laid with their slurry primer, but some professionals prefer a 4 to one mixture. We recommend seeking advice from the paving manufacturer or supplier regarding the recommended mortar ratios and primers.

Porcelain paving, like every type of paving slab, should always be laid on a full bed of mortar. Under no circumstances should paving slabs be laid on mortar dots or pads, a process referred to as ‘void bedding’. The body of the slab should be fully supported by the mortar. For more in formation regarding issues caused by dot and dab or void bedding of paving slabs, read our “Paving Problems” guide.

Due to the density of porcelain paving tiles they are more difficult to cut than porous natural stone and concrete slabs. Porcelain paving should be cut with a good quality continuous rim diamond blade. Beware of using course or cheap cutting disks, this is a false economy and risks chipping the edge and surface of the paving slabs. Porcelain paving can be cut with handheld petrol and electric disc cutters, but it might be worth hiring a bench saw for larger patios with lots of straight cuts as this will be quicker and more accurate.

The final stage of laying a porcelain patio is grouting or pointing. As porcelain paving is made to tight tolerances, with very little variation in size, grout joints can be narrower than for most natural stone and concrete paving, typically 5-10mm. For narrow grout joints a high-quality fine grain slurry grout is recommended. Be sure to clean away excess grout with a tiling sponge before it dries. Applying a pre-grouting treatment, such as Porcelain Tile Protector from Pavestone, will help to protect the slab surface from dried on grout residue.

Due to the uniform shape and straight edges of porcelain paving, it is possible to use slab spacers or a levelling system with spacers to easily create neat and tight grout lines.

Caring for porcelain paving slabs

One of the most appealing features of porcelain paving is its durability, unlike porous concrete and natural stone, porcelain paving does not require sealing to prevent staining and an occasional light scrub and rinse will keep the paving looking like new for years’.

It is not necessary to seal porcelain paving, it is resistant to staining, no more issues with split wine, hot fat from BBQs and acidic bird droppings, simply wipe them away. Porcelain paving will not fade in sunlight and is frost resistant. For more information paving care, read our “How to clean paving & patios” guide.

Benefits and disadvantages of porcelain paving

Porcelain paving is a fantastic product and there are very few if any downsides.

Benefits of porcelain paving

- Choice – The design or pattern on porcelain paving slabs is digitally printed and it is available in a huge variety of colours, patterns and natural effect finishes. Furthermore, porcelain wall cladding can also be purchased to match or contrast with paving slabs

- Durability – Porcelain paving is very dense, and this gives it great strength while being resistant to stains, moisture, sunlight and frost.

- Maintenance – Porcelain paving does not need to be sealed like many types of concrete and natural stone paving because it is resistant to dirt and staining, requiring only light washing to keep it looking as good as new.

- Quality – The manufacturing process for porcelain slabs ensures that there is very little variation in size and shape, this makes them easier to lay and narrower grout joints can be used.

- Weight – The strength of porcelain paving means they are generally thinner than equivalent concrete and natural stone slabs and this can make them lighter and easier to install.

Disadvantages of porcelain paving

- Price – Porcelain paving can be more expensive than concrete and some cheaper natural stone paving, although it should be noted that as porcelain paving has become more popular the price has dropped and is now comparable with good quality natural stone paving.

- Installation – While it is true that installing and cutting porcelain paving is a slightly more involved process, requiring slabs to be primed before installation, the same applies to many types of natural stone and porcelain paving does not need to be sealed. The benefits of porcelain slabs far outweigh any slight additional time and cost required to install it.

Finding an installer for porcelain paving

While it is true that porcelain paving is not difficult to install there are processes specific to porcelain that should be followed. If you intend to use a paving contractor to install your porcelain paving it is advisable to find a professional with porcelain paving experience. These resources may help you to find an appropriate paving contractor

https://www.pavestone.co.uk/highlighted-landscapers/

https://www.brettlandscaping.co.uk/find-an-installer/

No matter what type of paving you intend to use, it is advisable to view completed projects and speak to your preferred contractors’ customers before deciding who to employ to install your paving.

Porcelain paving is high quality, versatile and incredibly durable compared with other types of paving slabs. The variety of designs and patterns available creates endless design possibilities and the durability of porcelain means that it should look like new for many years with only the most basic of maintenance. If you would like to see examples of porcelain paving or would like more information, please do contact us or visit your local AWBS branch.

Download a copy of the AWBS Porcelain Paving Guide

Download a pdf copy of our porcelain paving guide here